Discover our Innovative PTFE Alternatives for a Wide Range of Applications and Systems

Regulatory requirements, including a potential EU ban on fluorinated polymers, lead to a demand for PTFE alternatives. Deuteron offers a versatile toolbox of functional PTFE alternatives based on high-performance polymers. Particularly suitable for low slip applications and mechanical resistance our materials are used in a variety of applications ranging from inks and coatings to lubricants and greases.

Advantages and Characteristics of Poly Methyl Urea as PTFE-Alternative

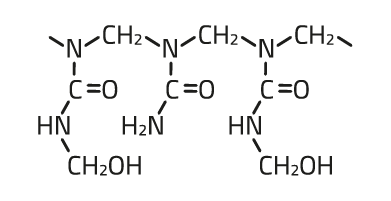

With our polymethyl urea chemistry (PMU), Deuteron offers an interesting functional alternative to PTFE-based additives. PMU is an organic, halogen-free polymer with a high molecular weight and high cross-linking density. PMU is a non-melting, extremely hard material which also shows a low coefficient of friction.

In ink and coating applications the addition of PMU based additives leads to significantly improved scratch and abrasion resistance and reduces the coefficient of friction (COF) – in applications where durability and slip are important PMU is an excellent functional alternative to PTFE.

Our PMU based additives are also suitable as PTFE replacements in lubricant applications such as greases and lubricating oils.

Due to the polarity of the polymer, it can be used in almost any system without compatibility problems and shows excellent wettability and intercoat adhesion.

Our PTFE-free solutions offer the following properties:

- Low coefficient of friction (COF)

- High mechanical resistance (scratches and abrasion)

- Broad compatibility / easy to disperse

- Excellent recoatability / intercoat adhesion

Technical properties and comparison vs. PTFE

Poly Methyl Urea (halogen free)

- Density: 1.46 g/cm3

- Melting point: non-melting

- Decomposition: > 200 °C

- Refractive index: 1.562

- OH content: ~0.25% (polar polymer)

- High hardness

- Low coefficient of friction

- Low haze

- Low influence on gloss

- Medium chemical resistance

- Excellent re-coat ability

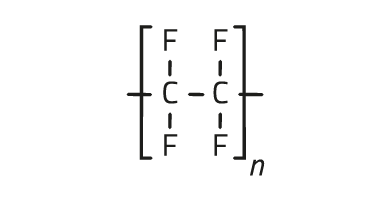

Polytetrafluorethylene

- Density: 2.20 g/cm3

- Melting point: non-melting

- Decomposition: ~ 345 °C

- Refractive index: 1.35

- Non polar (difficult to wet)

- Elastic

- Very low coefficient of friction

- Can cause haze

- Low influence on gloss

- Highest chemical resistance

- Anti-stick properties (omniphobe)

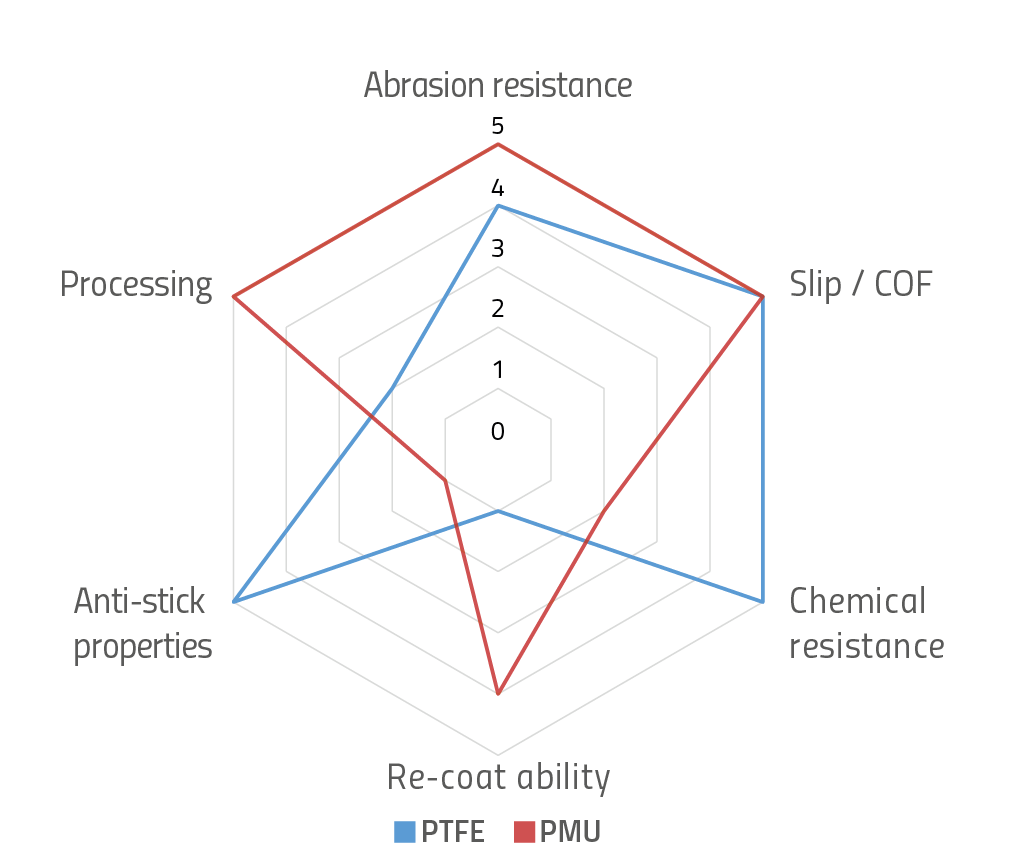

Performance of PMU vs. PTFE

- Abrasion resistance: Due to the high hardness of the polymer, the abrasion resistance of PMU is slightly superior to PTFE.

- Slip / COF: In many systems the use of PMU based additives leads to a surface slip (COF) similar to PTFE. The same is valid for the resulting scratch resistance.

- Chemical resistance: At low and high pH values the PMU molecule can undergo hydrolysis. In standard ink and coating systems this effect usually is not relevant.

- Re-coat ability: PMU shows an excellent compatibility to most systems and does not interfere with intercoat adhesion or re-coat ability.

- Anti-stick properties: Contrary to PTFE the anti-stick performance of PMU is not existent. The use of PMU usually does not lead to anti-stick properties.

- Processing: Due to it’s polar molecule PMU is usually very easy to disperse and highly compatible in most systems – especially in water-based applications.

Deuteron’s PTFE-Alternatives

Our portfolio includes a variety of different products that differ in terms of particle morphology, particle size and preparation form. Due to the complexity of the topic, our technical service will be happy to support you in selecting suitable products for your specific application. Discover our solutions to prepare your system for a PTFE-free future.

Powder

- Must be properly dispersed

- Highest compatibility

DEUTERON SF 505

Coarse powder

d50: 7 µm

d99: 18 µm

DEUTERON SF 707

Fine powder

d50: 4 µm

d99: 12 µm

Liquid Preparations

- Easy to use

- Available in different

solvents

DEUTERON OG 861

Solvesso 150 ND

32 % active

50: 3,5 µm

d99: 12 µm

DEUTERON OG 863

Isopropyl alcohol

32 % active

d50: 3,5 µm

d99: 12,5 µm

DEUTERON OG 8670

Water

22 % active

d50: 3,5 µm

d99: 12,5 µm

DEUTERON OG 8820

TMP(EO)3TA

30 % active

d50: 3,5 µm

d99: 12 µm

Low Coefficient of Friction

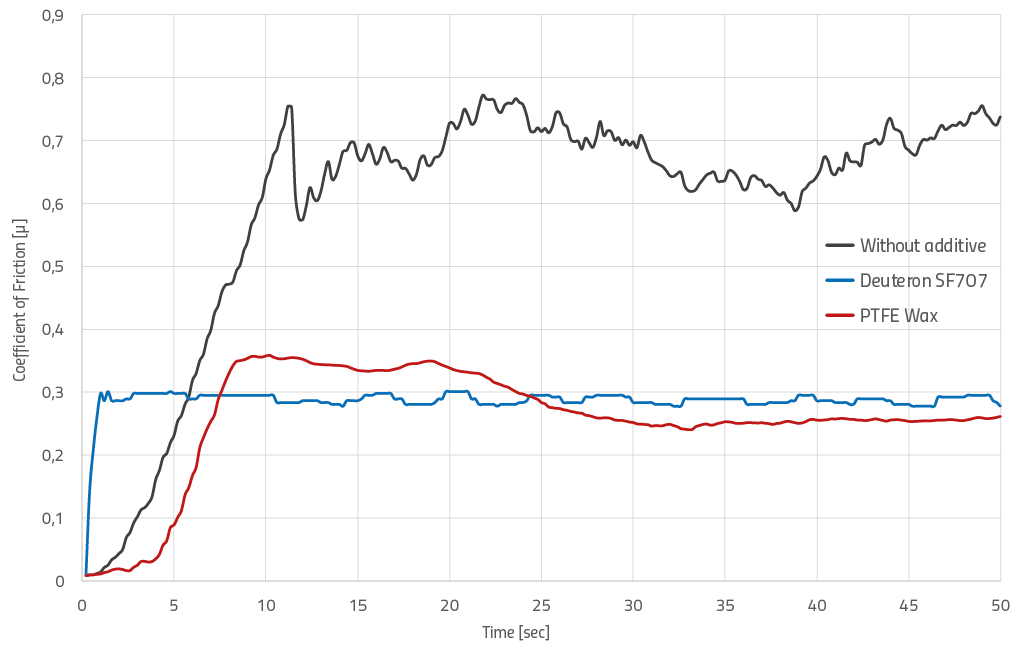

The coefficient of friction (COF) defines the smoothness or slip of a film. PTFE is used in particular due to its low COF and the associated advantages. A low COF leads to lower friction and greatly improved scratch resistance.

The direct comparison shows that Deuteron SF 707 achieves a surface smoothness similar to PTFE. This key property and all linked advantages of PTFE can be substituted by the use of PMU products.

Scratch and Abrasion Resistance

The mechanical resistance to scratches or abrasion is another important reason for using PTFE. PTFE works almost exclusively via its improved COF properties, which make it more difficult for scratching or abrasive bodies to penetrate into the coating.

Our PMU polymers work in two different ways: the reduced COF improves scratch resistance in exactly the same way as PTFE. In addition, the PMU particles is comparably hard and resistant – this significantly improves the abrasion resistance even further.

Ready for the Next Step?

In many applications surface additives based on poly methyl urea can be an interesting alternative to expensive products containing PTFE. Due to its high hardness and comparatively low COF, PMU can completely or partially replace PTFE based additives. We are happy to support you with free samples for your own trials. Our technical field service will contact you on request to clarify technical details in a personal discussion and identify the most suitable product for your specific application.